About GKN Powder Metallurgy

Through world-class powder metallurgy technology, GKN Powder Metallurgy meets the complex challenges of the automotive and industrial markets with sustainable and innovative solutions. Operating globally, the company is a leading supplier of powder metallurgical materials, components, applications and electric motor solutions.

GKN Powder Metallurgy consists of GKN Powders/Hoeganaes, GKN Sinter Metals and GKN Additives, three businesses under one brand. With more than 5,000 innovative minds in 27 manufacturing locations, GKN Powder Metallurgy sets the highest standards with its global engineering network.

Bruneck/Sand in Taufers is one of the most successful production sites. The Bruneck plant has been in operation since 1967, while the Sand in Taufers plant is a 2017 addition. A total of around 680 people are employed at the two sites. Working together as a dynamic, customer-focused team, our goal is to be the market leader in the design, manufacture and supply of a wide range of sintered metal components, sintered products and services to our customers worldwide.

Please visit our corporate website to learn more about GKN Powder Metallurgy.

Our manufacturing process

Powder Metallurgical Sintering – featuring innovative near-net-shape forming, is one of the most cost effective ways to produce high volume parts with the highest dimensional accuracy, repeatability, cleanliness and quality requirements. In addition, the process is extremely friendly to the environment.

How our process works

01

Product & Tooling Design

Product and tooling design and manufacturing.

02

Powder Blending

Raw material in powder form is blended in accordance with product requirements.

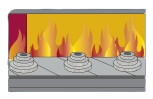

04

Sintering

To achieve the required strength, the blanks are sintered in an oven at approximately 1,120°C.

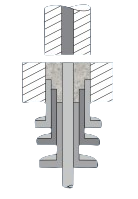

03

Pressing

Special tools are used to press the powder. These parts are referred to as “green compacts”. The pressure is 400 – 800 MPa.05

05

Calibration

By calibrating, both dimensional accuracy and density are increased and the surface is improved.

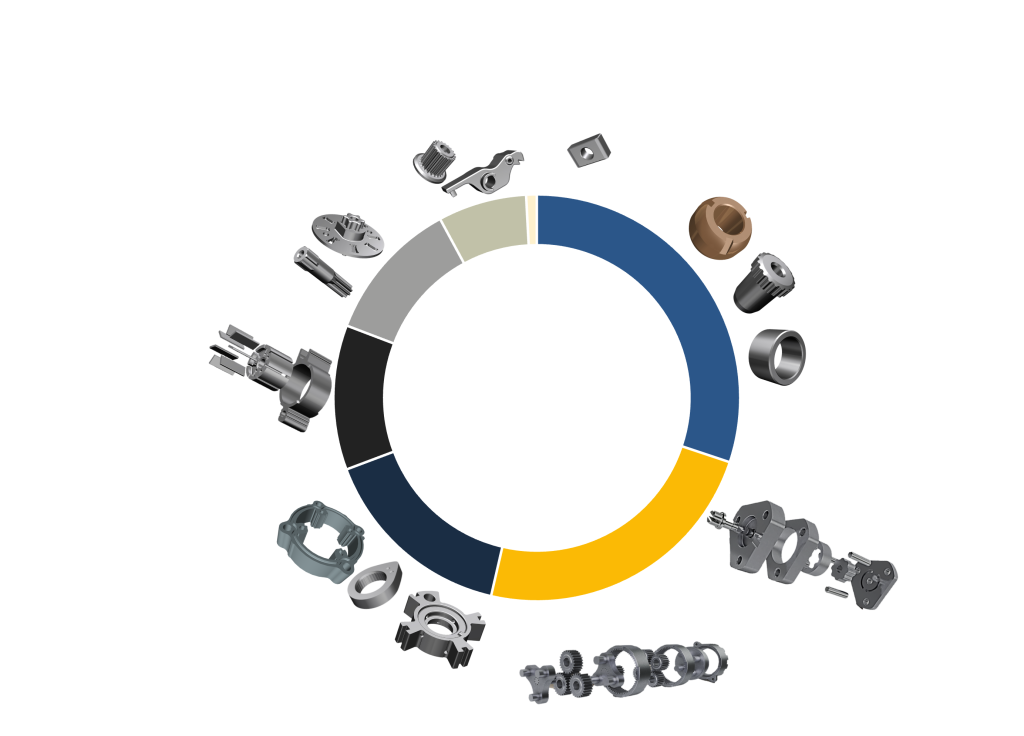

Product groups

- Parts produced: 1,457,755,366

- Other parts: 2,347

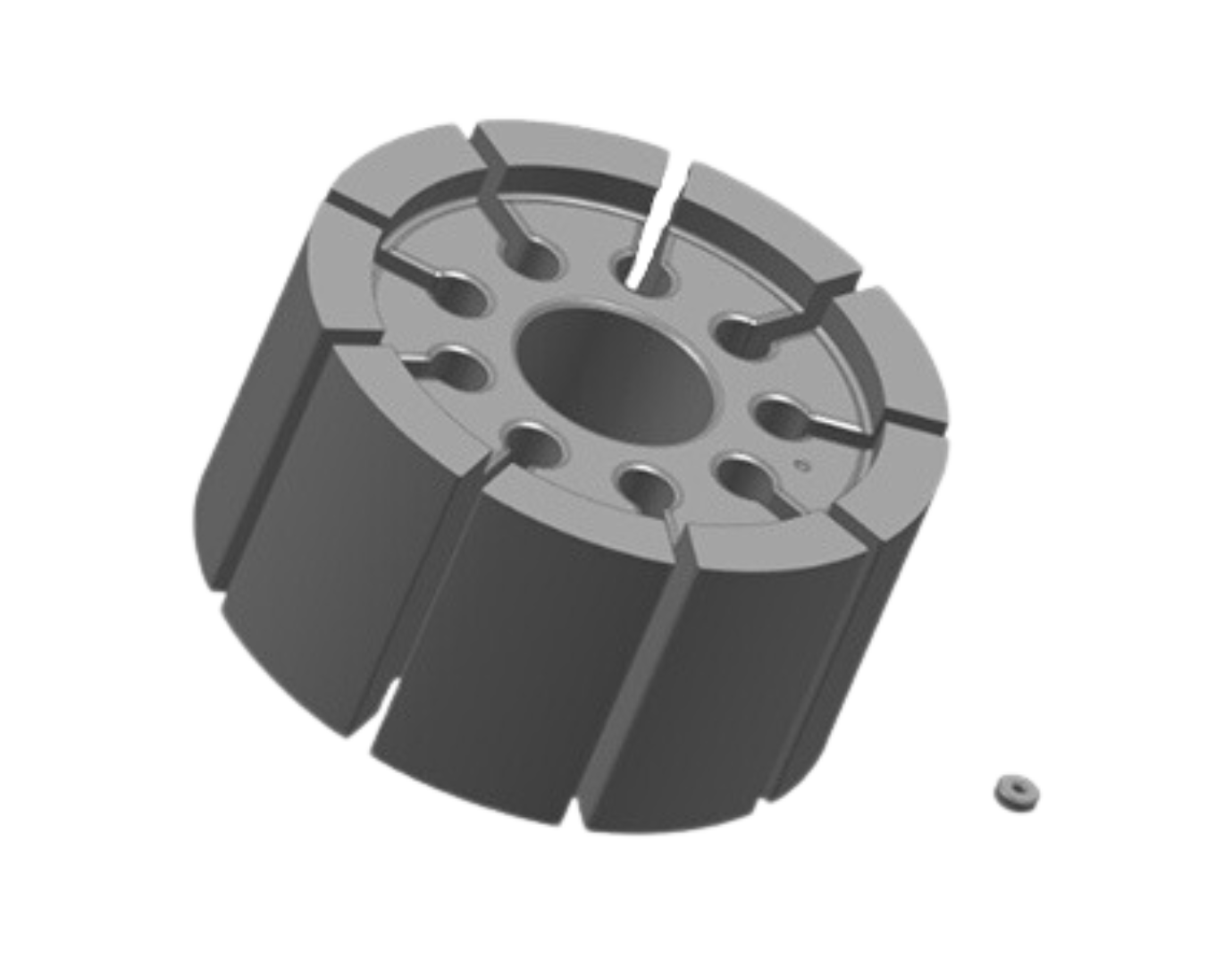

Largest component

- Outer diameter: 59 mm

- Height: 30 mm

- Weight: 400 g

Smallest component

- Outer diameter: 4 mm

- Inner diameter: 1 mm

- Height: 1.5 mm

- Weight: 0.12 g